How to Create a Mobile App for the Manufacturing Industry

In an era where technology drives efficiency and innovation, mobile applications have become indispensable across various industries. Among these, the manufacturing industry has shown significant potential for adopting mobile technology to enhance productivity, streamline operations, and improve communication. Mobile app developers are at the forefront of this transformation, playing a vital role in crafting applications tailored to the unique needs of manufacturers. Here’s a comprehensive guide on how to create a mobile app for the manufacturing industry.

Understanding the Industry’s Requirements

Before diving into the development process, it’s crucial to thoroughly understand the manufacturing industry’s needs and challenges. Manufacturing encompasses various sectors, from automotive and electronics to textiles and machinery production. Each sector has distinct operational workflows, pain points, and goals. Mobile app developers should start by conducting in-depth research to identify common requirements such as inventory management, real-time monitoring, machine maintenance scheduling, and workforce collaboration. Understanding these aspects helps in designing an app that addresses specific industry challenges.

Designing a User-Centric Interface

A manufacturing mobile appmust prioritize user experience (UX) and user interface (UI) design. Factory floor workers, supervisors, and managers may have varying levels of technical proficiency, so the app’s interface should be intuitive and accessible. Mobile app developers need to create a design that simplifies complex tasks, offers clear navigation, and ensures seamless interaction. For instance, using large icons, easy-to-read fonts, and color-coded alerts can enhance usability in fast-paced manufacturing environments.

Integrating Essential Features

To make the app functional and relevant, developers must focus on integrating features that cater to the industry’s specific needs. Real-time tracking and monitoring are pivotal, allowing managers to oversee operations remotely and make data-driven decisions. Additionally, inventory management features can streamline the supply chain, reducing delays and minimizing stock discrepancies. Including predictive maintenance functionalities helps prevent machinery breakdowns by analyzing usage data and alerting users about potential issues. Mobile app developers should also consider adding communication tools to foster better collaboration among teams, ensuring smooth workflow coordination.

Leveraging Advanced Technologies

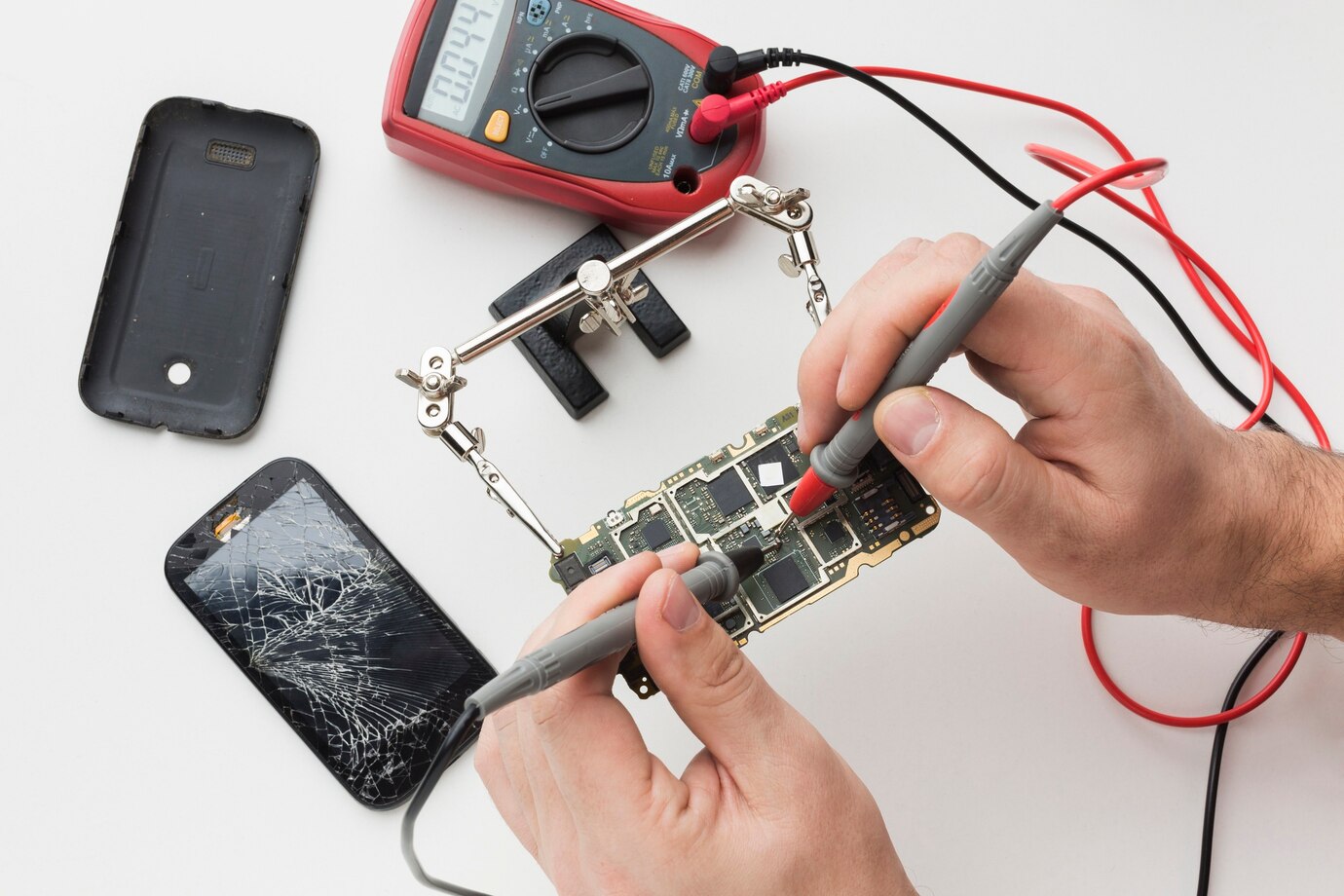

Incorporating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and augmented reality (AR) can elevate the app’s functionality. IoT integration enables the app to connect with manufacturing equipment, providing real-time data on performance, energy consumption, and operational status. AI-powered analytics can help predict trends, optimize production schedules, and enhance quality control. AR features, on the other hand, can assist in training employees by offering immersive, on-the-job tutorials or aiding technicians in complex repairs. Mobile app developers must evaluate which technologies align best with the client’s objectives and budget.

Ensuring Scalability and Flexibility

Manufacturing operations often evolve, with businesses scaling up or diversifying their processes. Mobile app developers should design apps that are scalable and flexible enough to accommodate these changes. Opting for a modular architecture allows developers to add or modify features without disrupting existing functionalities. Cloud-based solutions also offer scalability, enabling manufacturers to manage increasing data volumes and expanding user bases without significant infrastructure investments.

Prioritizing Data Security

Given the sensitive nature of manufacturing data, including intellectual property, production schedules, and client information, ensuring robust security measures is paramount. Mobile app developers should implement encryption protocols, secure authentication mechanisms, and regular software updates to protect the app against cyber threats. Compliance with industry regulations, such as GDPR or CCPA, is also essential to maintain trust and avoid legal repercussions.

Testing and Deployment

Comprehensive testing is a critical phase in mobile app development for the manufacturing industry. Developers must conduct rigorous testing to identify and fix bugs, ensuring the app functions flawlessly under different scenarios. Performance testing evaluates how the app handles high loads, while usability testing ensures it meets user expectations. Once testing is complete, the app can be deployed across the intended platforms, such as iOS, Android, or both. Mobile app developers should provide clear documentation and training resources to help users transition smoothly to the new technology.

Continuous Support and Updates

The journey doesn’t end with the app’s launch. Mobile app developers need to offer continuous support to address user feedback, fix issues, and implement updates. Regularly adding new features and enhancements based on technological advancements and user needs helps maintain the app’s relevance and effectiveness. By fostering an ongoing partnership with manufacturers, developers can ensure the app remains a valuable asset in their operations.

Conclusion

Creating a Mobile App for the manufacturing industry requires a deep understanding of the sector’s intricacies, a user-centric design approach, and the integration of advanced technologies. Mobile app developers play a crucial role in driving innovation, enabling manufacturers to achieve operational excellence and stay competitive in a rapidly evolving market. By focusing on scalability, security, and continuous improvement, developers can deliver solutions that empower the manufacturing industry to thrive in the digital age.